How do recycled plastic bottles from the ocean get transformed into fabric for your jackets?

The process of transforming recycled plastic bottles from the ocean into fabric for jackets, such as the TIDAL TACTICS EXPEDITION down jackets, involves several steps.

It begins with the collection of plastic bottles from the ocean, which are then thoroughly cleaned and sorted by type, focusing specifically on PET plastic. These bottles are shredded into small flakes and melted down into a molten plastic mass. This molten plastic is extruded through fine holes to create thin fibers, which are then spun into yarn. The yarn is woven or knitted into fabric, depending on the desired texture and function. The fabric undergoes finishing processes, including dyeing and treatment, to enhance its durability and appearance.

Finally, the finished fabric is cut and sewn into the TIDAL TACTICS EXPEDITION down jackets. This process turns ocean waste into sustainable, high-performance outerwear, embodying both environmental responsibility and functional design.

Can you explain the process behind your CO₂ extraction and removal projects in collaboration with Stripe Climate?

APACHE STAR partners with Stripe Climate to support carbon extraction and removal projects as part of a broader effort to combat climate change. No company can tackle climate change alone, which is why Stripe Climate brings together over 25,000 forward-thinking companies across 39 countries to aggregate demand for CO₂ removal.

Through this partnership, APACHE STAR donates 1% of its revenue to Stripe Climate, which selects and funds carbon reduction projects worldwide. These projects employ various techniques, such as Direct Air Capture (DAC) to capture CO₂ from the atmosphere, ocean-based methods to enhance natural carbon absorption, and biomass or soil sequestration for permanent carbon storage.

The captured CO₂ is either stored underground or converted into long-lasting materials, with all projects undergoing rigorous monitoring and verification. By participating in this global initiative, APACHE STAR helps spread effective solutions and makes a significant contribution to reducing atmospheric carbon.

Direct Air Carbon Technology (Photo courtesy of Carbon Engeenering)

Can you describe the methods used to create plastic-free shipping materials and ensure their effectiveness in protecting your products?

The development of plastic-free shipping materials focuses on environmentally friendly alternatives that effectively protect our lifestyle kits. We use biodegradable and compostable materials, such as paper, cardboard, and cornstarch-based packaging, which are both durable and recyclable. Natural fillers, like shredded paper and wood wool, cushion our products while being fully biodegradable. We also use paper tape with natural adhesives, replacing traditional plastic tape.

Additionally, our high-performance jackets are shipped in sustainable leather covers, offering optimal protection during travel and aligning with our commitment to eliminating plastic. Our packaging is carefully designed for both fit and protection, with all materials rigorously tested to withstand the challenges of shipping.

How do you balance the need for durable, high-performance materials with sustainability goals?

APACHE STAR achieves a balance between durability and sustainability by choosing materials that are both high-performance and eco-friendly, such as recycled plastics and sustainably sourced fabrics. We employ advanced technologies to enhance material strength while minimising environmental impact.

Our practices include using recyclable packaging and reducing waste during production. All materials undergo rigorous testing to ensure they meet high-performance standards while remaining environmentally responsible. Furthermore, we continually explore new sustainable materials and technologies to further improve both durability and sustainability.

What upcoming innovations and trends in materials and design is APACHE STAR excited to explore in the next five years?

Over the next five years, APACHE STAR will explore several key innovations. We aim to integrate advanced sustainable materials, such as bio-manufactured textiles and improved recycled fabrics, offering enhanced durability and environmental benefits.

We are also exploring smart fabrics with integrated technology for real-time performance monitoring, along with adaptable materials. Circular design principles will be applied to create products that are more recyclable and durable.

Additionally, we plan to utilise 3D printing for customised designs and to reduce production waste, while researching new eco-friendly finishing techniques that improve fabric performance and sustainability. These innovations will allow us to lead in both design and environmental responsibility.

ABOUT THE BRAND

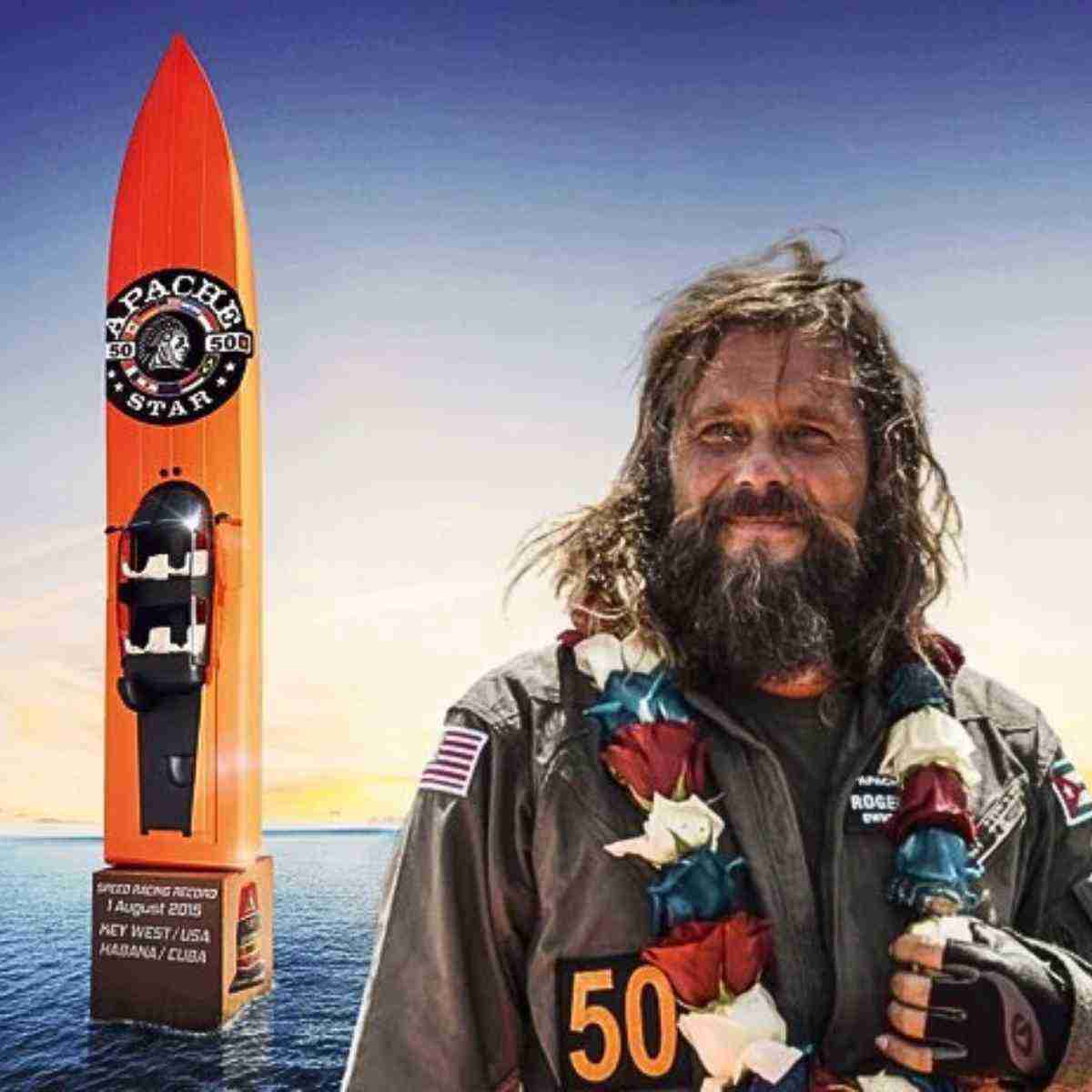

APACHE STAR is a fashion and lifestyle label inspired by the rebellious spirit of extreme athlete Roger Klüh. In 2015, Klüh set a world record by crossing from the USA to Cuba in the two-time World Champion Powerboat, Apache Star. The brand’s adventure kits are designed for those who can't be pigeonholed, offering the confidence to achieve even the highest goals. APACHE STAR pays tribute to this bold and daring spirit, empowering individuals to embrace their own potential.

Source: tocco.earth | 06.12.2024

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.